Ibha Yensimbi

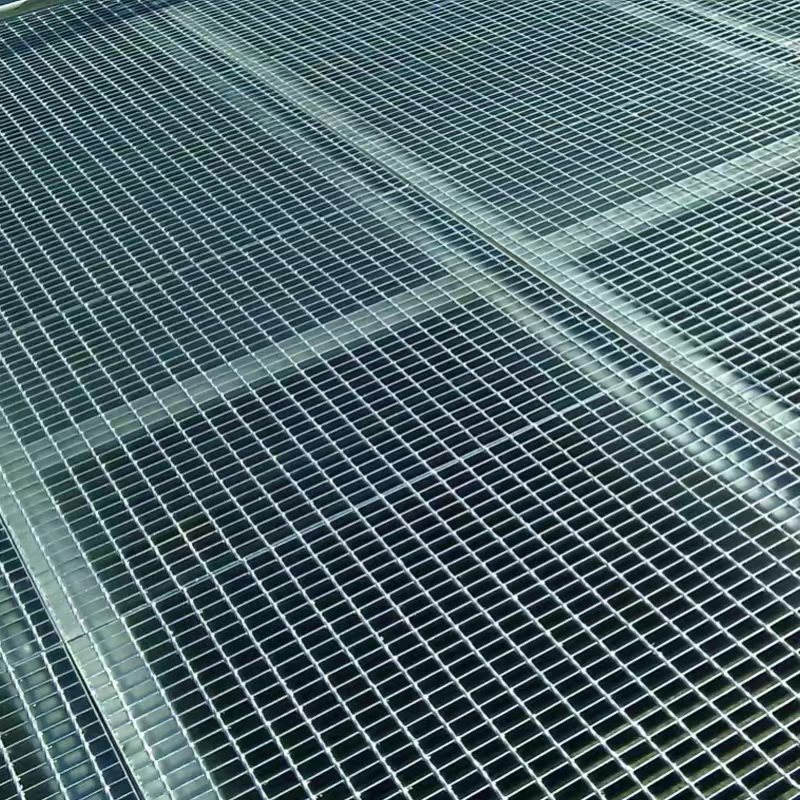

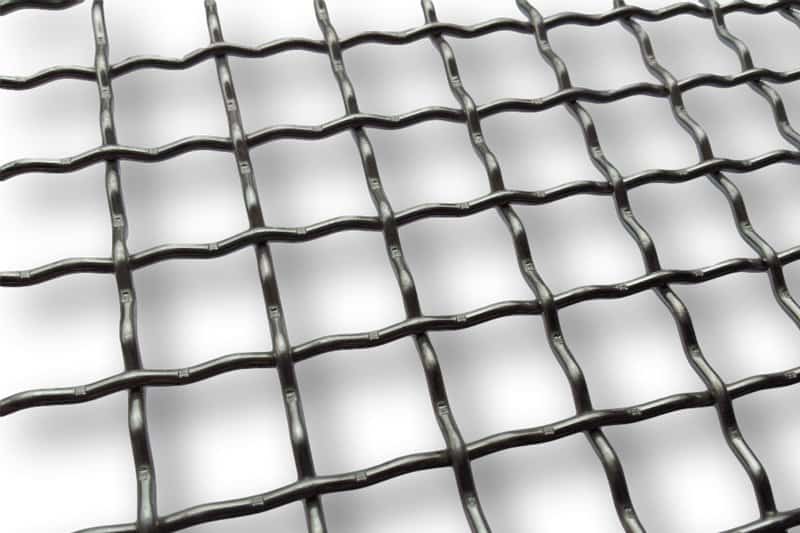

Ibha Yensimbiiyibha yesigaba esiphambanayo esingunxande esishiselwe noma esiboshiwe ekucushweni okuningi ukuze kukhiqizwe i-bar grate njengesistimu ye-flooring ezinhlobonhlobo zezicelo.

Imininingwane Yomkhiqizo

Omaka bomkhiqizo

Ibha Yensimbiiyibha yesigaba esiphambanayo esingunxande esishiselwe noma esiboshiwe ekucushweni okuningi ukuze kukhiqizwe i-bar grate njengesistimu ye-flooring ezinhlobonhlobo zezicelo.

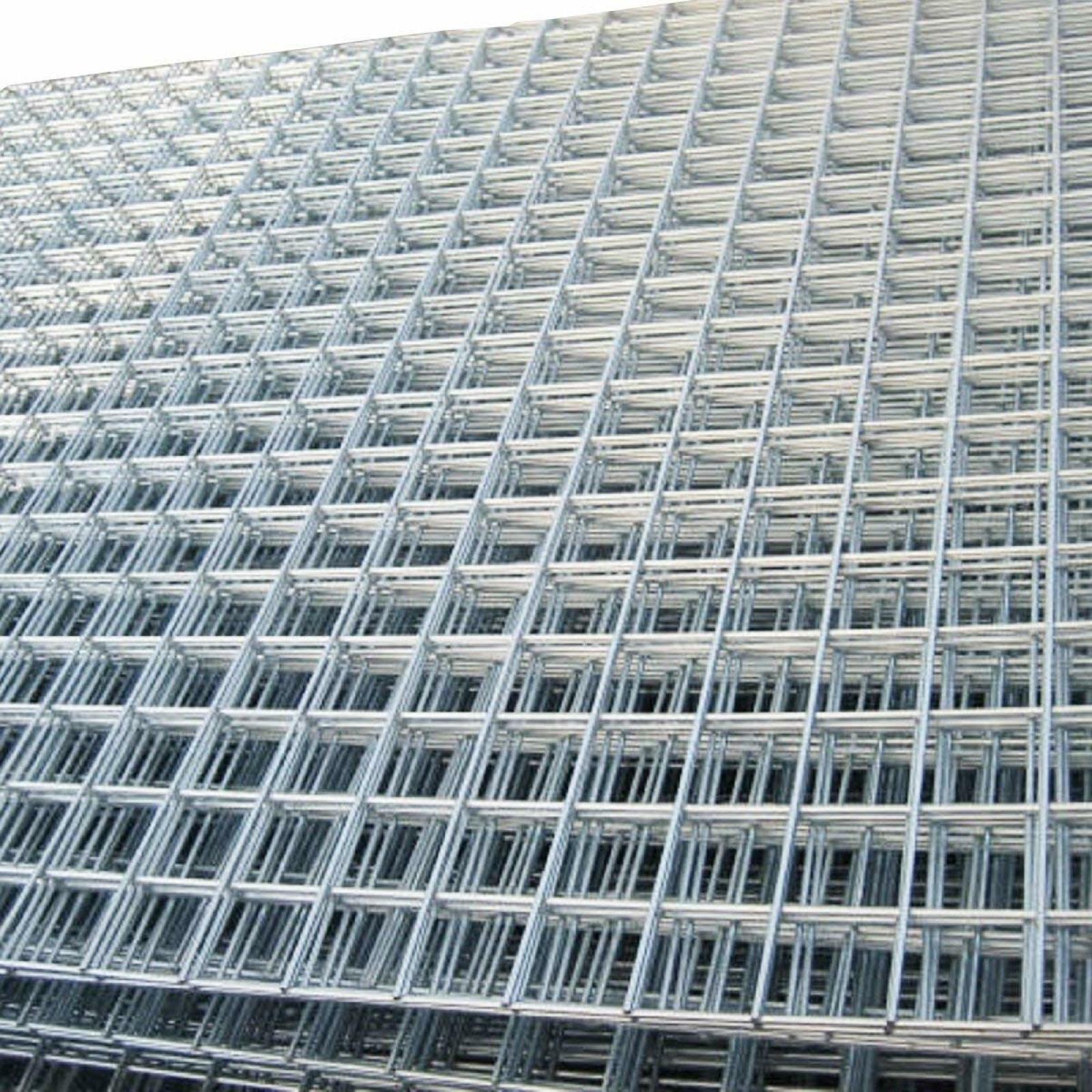

I-bar grate iyisakhiwo sensimbi esihlinzeka ngezinzuzo eziningi ngaphezu kwezinye izinto futhi ingasetshenziswa phezu kwezicelo ezihlukahlukene, kuhlanganiseImpahla yezimboni kanye nempahla yokugcina, izindlela zokuhamba, imigudu, imisele, namapulatifomu.

Uma ungathanda ukuba ne-steel bar grating.Ungaba nazo ngemibala ehlukene futhi azikwazi ukugqwala.Lezi zingasetshenziswa ezinhlelweni eziningi.Okufana nokuklama, ukuphepha, izakhiwo, njll.

Ungase ukwazi lokhoinsimbi bar gratingikhona kumabhilidi amaningi, amabhuloho, nezinye izakhiwo.Singakunikeza ukusika nge-laser ye-steel bar grating yakho kanye nokushisela.

Amagridi ensimbi angagibela phansi.Futhi isetshenziselwe ukunikeza indlela yokuhamba ezindaweni lapho kunamazinga aphezulu abantu abahamba ngezinyawo.

Imigoqo eku-grating ingahlukaniswa ukuze ingabi ngaphezu kuka-2 futhi ngezinye izikhathi ihlukane ngamasentimitha angu-1.5.Lapho ufaka i-steel floor grating.Kubalulekile ukuvumela ukuvuleka okume mpo okungengaphansi kwamafidi angu-5 phakathi kwendawo ephansi kanye nephansi legrayiti.

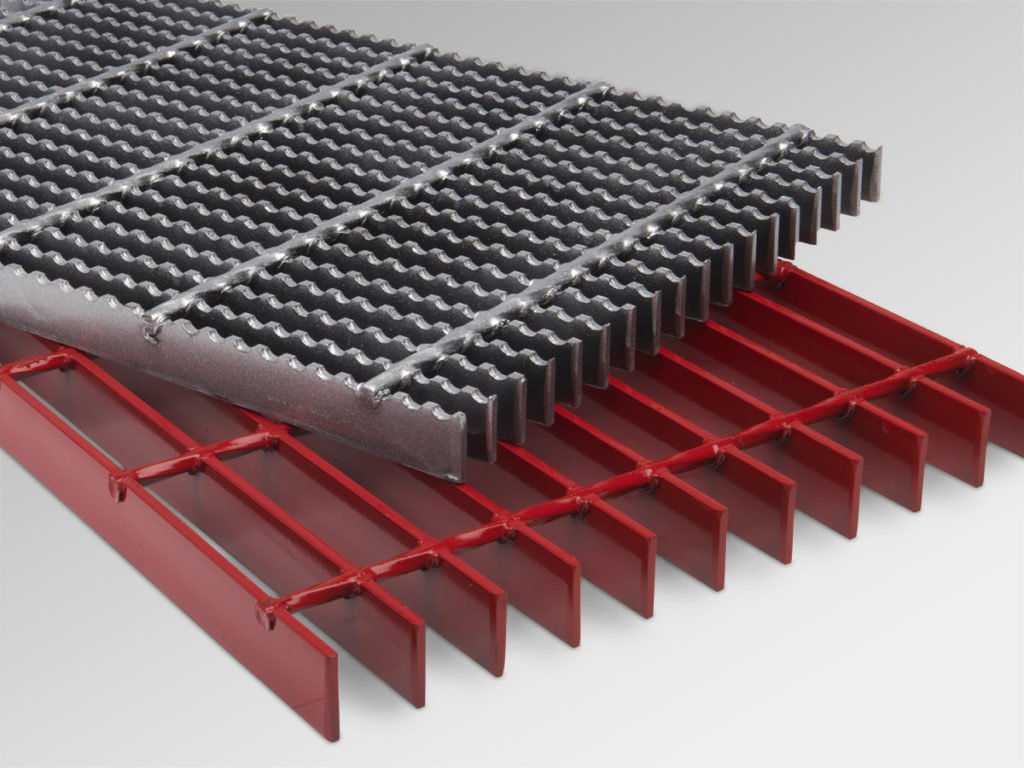

Ukucaciswa kwe-steel bar gratings

| Okubalulekile | Insimbi ye-carbon ephansi, insimbi engagqwali noma ezinye izinto |

| Ibha yokuthwala | 30mmHeight * 5 mmTHK(uhlobo oludumile), noma ngokwezidingo zakho |

| Tie rods: | 6mm, 8mm noma ngokwezidingo zakho |

| Isikhala se-Cross Bar | 100mm noma nge-reuirements yakho |

| Ukwelashwa kwendawo | Okushisayo okucwiliswe uthayela |

I-steel grating

Izinsimbi zensimbi, ebizwa nangokuthi ama-bar grates noma ama-gratings ensimbi, uhlaka oluvulekile olwakhiwe ngamabha noma ama-rails.Imigoqo yensimbi "ye-grating" igijima ohlangothini olulodwa ngenkathi imishayo ye-diagonal.Noma ama-crossbar amile futhi asebenza njengemishayo yokusekela.

Ukuxhuma okuxhumayo kwenza umklamo ovame ukususelwe kumamojula angama-8-foot.Okuyizifaki eziningi ezilingisayo emsebenzini wazo.Emashumini eminyaka lawa magridi asetshenziselwa ukwakha phansi (ikakhulukazi phansi kwefekthri), ama-mezzanines, izitebhisi, amapaneli okubiya, izembozo zemisele kanye nezinkundla zokulungisa.Futhi zingasetshenziselwa ukulawula umsindo emigwaqweni emikhulu nezinye iziteshi zokuthutha.

Insimbi yensimbi isetshenziselwa ini?

I-steel gratingwuhlobo lwe-flooring olusetshenziselwa izinhloso eziningi ezahlukene.Izimboni eziningi zisebenzisa i-grating phansi.Ngoba kungavimbela umonakalo kanye nezingozi zokuwa kubasebenzi.

Kwesinye isikhathi isetshenziselwa amasistimu okuthutha nawo.Kanye nemishini engaguquki edinga ukusekelwa phansi.Eqinisweni, ngezinye izikhathi isetshenziswa njengesithiyo samanzi ukuvimbelaizikhukhula.

I-steel gratingiphinde isetshenziswe embonini yezokwakha ukuze imboze ingaphandle lesakhiwo ukuze kwengeze ukuphepha nokuvikeleka, ngokuvamile ngendlela yomzila.

Iphinde isetshenziswe emagaraji okupaka kanye nasezindaweni zokugcina izimpahla ukuze kufinyelelwe kwesinye isitezi.Kubalulekile lokhoi-steel gratingifakwe ngendlela efanele ukuze kuvinjelwe abasebenzisi ukuthi babhekane nezimo eziyingozi.

I-steel floor grating

I-steel floor gratingiyingxenye ebalulekile yanoma yimuphi umsebenzi wokwakha.Njengoba kunjaloukumelana nakho kokubili umlilo nokulimala, kungandisa ukuqina kwesakhiwo.

I-steel floor gratingingasikwa futhi ihlanganiswe ndawonye ukuze kwakhiwe imigqa ehlanzekile namajamo.Ngakho-ke zingaba inketho ekahle yokwakha noma ukulungisa kabusha.

Kuye ngokuthi i-flooring isetshenziselwa ini, ingapendwa noma ifakwe amabala.Zonke izinto zokwakha ziza ngosayizi abajwayelekile ukuze zifakwe kalula.

I-ASX METALS ingumkhiqizi wokugaya insimbi.Futhi sidala imikhiqizo yekhwalithi ephezulu ephephile, ethembekile, futhi emihle ukuthi ibukwe.

Sikhiqiza izinga eliphezulu, eliqinile.I-grating ethengekayo efanele ukusetshenziswa okuhlukahlukene.Njengasemakhaya, amabhizinisi, nezinye izikhungo.Phequlula iwebhusayithi yethu ukuze uthole ulwazi olwengeziwe mayelana nemikhiqizo yethu.

Izinzuzo ze-steel floor grating

I-Steel Floor Gratinginenani elikhulu lezinzuzo ngaphezu kwezinye izinketho zokubeka phansi njengezinkuni.Insimbi iyinto ehlala isikhathi eside, ekwazi ukumelana nesisindo esinzima kanye nomthelela.

Iphinde imelane cishe nanoma yiluphi uhlobo lwesimo sezulu.Ngakho-ke noma unendlu yokugcina impahla ngaphandle ezweni, iphansi lakho ngeke ligoqe noma liqhekeke!

I-grating ewugqinsi iphinde inikeze ukuvikeleka okwengeziwe.Futhi uqinisekisa ukuthi akekho ozobamba izinyawo zakhe phansi.Awufuni ukuthi indawo yakho yokugcina impahla ibe icala.Ngoba othile wakhubeka phezu kwegridi ethile.

Inzuzo eyinhloko yokusebenzisa i-steel floor grating ukuthi ihlala isikhathi eside.I-steel floor gratingihlala isikhathi eside, ngakho izomelana novivinyo lwesikhathi.

Le mpahla imelana nezinhlobo eziningi zamakhemikhali noketshezi.Okwenza ilungele izinhlelo zokusebenza ezihlukahlukene.

I-steel floor gratingfuthi imelana ngokuphelele nomlilo nokuhuzuka.Ayinankinga yokumelana nokuguga kokusetshenziswa kwansuku zonke.

Uzophinde ujabulele inani elithengekayo le-steel grating.Le nto ishibhile kakhulu kunezinye izinhlobo zokugaya phansi.Ngakho ungonga imali eningi uma ukhetha i-steel grating.

Isikhathi sokuphila se-steel floor grating

Insimbi yesakhiwo, njengazo zonke insimbi.Iyakwazi ukugqwala lapho ibhekene nezimo ezithile zemvelo.Ukugqwala, okwaziwa nangokuthi ukugqwala, ukuwohloka kwensimbi echayeke emanzini noma kumswakama.Ukuchayeka ekukhanyeni, ekushiseni, nakumoya-mpilo.Kuhlanganisa nomoya-mpilo okhona emoyeni, nakho kunomthelela ekugqwaleni.

Ukuphila kwe-steel flooring yakho kuzoncika ezintweni eziningana.Njengesimo sezulu kanye nezimo zokugcina.Inani lethrafikhi yezinyawo, noma ngabe usebenzisa i-coating yokuvikela, njll.

Ukugaya phansiyakhelwe ukuhlala okungenani iminyaka engama-20.Futhi ingasetshenziselwa kokubili izindawo zasendlini nezangaphandle.

Ukwandisa isikhathi sokuphila semikhiqizo yakho yokugawula phansi kwensimbi.Sincoma ukuthi uhlole insimbi yakho ukugqwala.Futhi lungisa insimbi lapho itholakala.

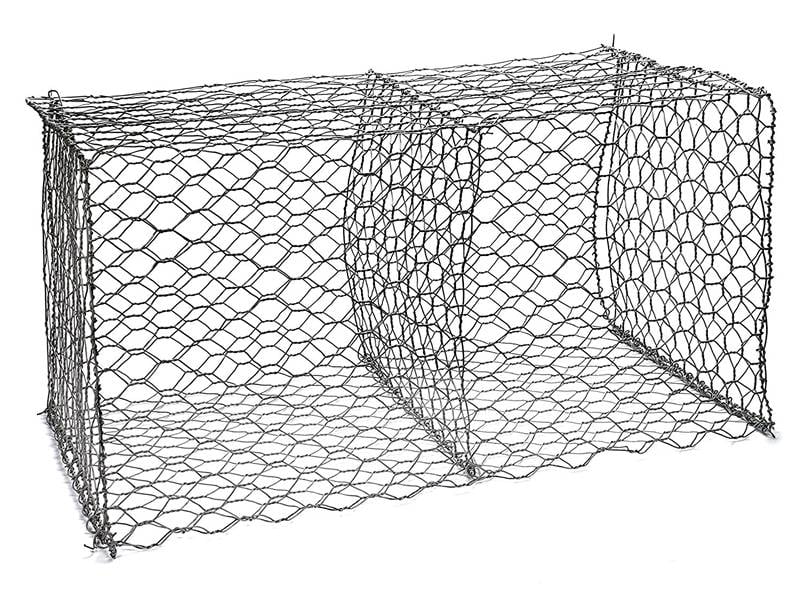

Igridi yensimbi engagqwali

Igridi yensimbi engagqwaliluhlobo lwe-graft equkethe ucezu oluncane lwensimbi engagqwali.Insimbi engagqwali iqinile futhi imelana nokugqwala.

Ukwenza kube yinto evamile yokugaya.Isizathu sokuthi idume ukusetshenziswa ekugayeni ukuthi nayo injaloukumelana nokugqwalafuthi imelana namakhemikhali.

Igridi yensimbi engagqwaliisici esivame ukunganakwa emakhishini njengoba sibalulekile.Nge-grating yensimbi engagqwali, ungavikela iphansi lakho nezinto zokubala ekushiseni.

Iphinde ibukeke ibushelelezi kuyilapho okunye okokusebenza kungase kungathandeki.Kubalulekile ukuqaphela ukuthi izinto ezahlukene zingase zidinge izinqubo ezahlukene zokunakekelwa nokuhlanza.

Igridi yensimbi engagqwali ayidingi ukulungiswa.Iphinde imelane nokugqwala okusho ukuthi iqinile.Kulula futhi ukulihlanza, ukuze ukwazi ukugcina ikhishi lakho lihlanzekile ngaso sonke isikhathi.

Izinzuzo zokugawula insimbi engagqwali

Kunezinhlobo ezintathu eziyinhloko zensimbi: i-carbon, i-alloy, ne-stainless.Insimbi engagqwali iyingxenye 'engenasici' yegama ngenxa yokuthi yenziwe okungenani nge-chromium engu-10.5%.

Okuyinikeza ukumelana okuhle nokugqwala nokugqwala.Insimbi engagqwali iyingxubevange, okuyilapho izinsimbi ezimbili noma ngaphezulu zincibilika ndawonye ukuze zakhe ingxubevange.

Ngaphandle kokumelana nokugqwala.Insimbi engagqwali inokubekezelela ukushisa okuphezulu futhi kulula ukusebenza ngayo.Insimbi engagqwali iyinto efanelekile yokugaya.Ngoba ayibizi, ayisindi futhi ihlala isikhathi eside.

Izinzuzo ze-Stainless Steel Grating:

- Imelana namabala nokugqwala

- Ukumelana nokugqwala

- Impilo ende

- Izinto ezihlala isikhathi eside

- Ikhono lokubamba isisindo esikhulu

- Ukonga izindleko

Izicelo ze-grating yensimbi engagqwali

Igridi yensimbi engagqwaliiyinto ehlala isikhathi eside, ekwazi ukumelana nokugqwala.Lokho kusetshenziselwa izinhlelo zokusebenza ezihlukahlukene zasendlini nangaphandle.

Kuyinto evame kakhulu.Isetshenziselwa izindlela zokuhamba, izindawo zokudlala, izindawo zokudlela, nezinye izinhlelo zokusebenza eziningi zentengiso.

I-grating yensimbi engenasici inezinhlobonhlobo zezinhlelo zokusebenza.Nazi izibonelo ezimbalwa:

- Izindonga zomhubhe wokuhamba ngocezu olukhulu

- Ukuhlinzeka ngokuphepha nokuvikeleka ezindaweni zokwakha

- Ukuvikela ingaphezulu, kanye nokugcina izinga lamanzi emizileni yamanzi nasemachibini

- Iwusizo ekuhlungeni amanzi nomoya

Ukugcinwa Kwensimbi Yensimbi

Nakuba kungadingekile ukugcina i-grating yaphansi, kuhle ukuyihlanza ngezikhathi ezithile.Ngokuvamile, ukuhlanza kufanele kwenziwe njalo ngemva kwezinyanga ezimbalwa uma kunokungcola okuningi kuyo.

Lokhu kungenxa yokuthi ukungcola kuzovaleleka ku-grating okubangela izinkinga njengokushelela.Ukuyihlanza, ungasebenzisa i-mop, isipontshi noma amanye amathuluzi okuhlanza.

Qinisekisa ukuthi usebenzisa imikhiqizo yokuhlanza kuphela ephephile ukuthi isetshenziswe ku-grating yaphansi.Ngoba asifuni ukudala umonakalo phansi.